Our manufacturing processes are fully automated and tailored to the machining of parts. We comply with the market’s expectations in terms of quality and competitiveness.

Manufacturing facilities and laboratory

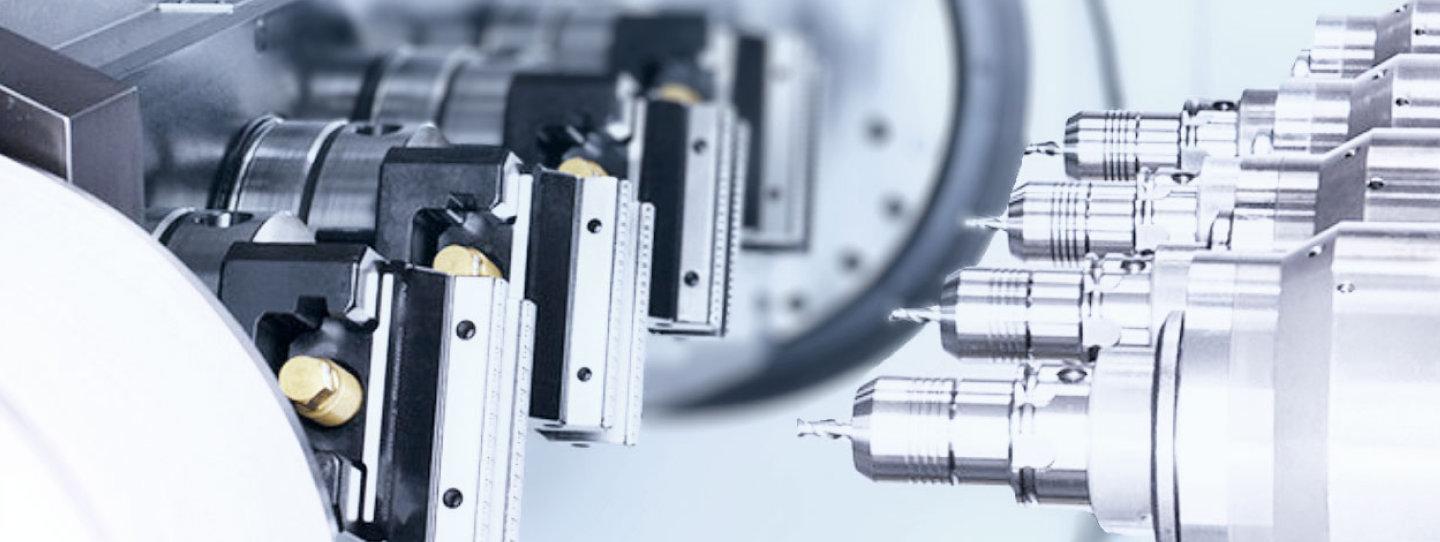

We have several units with one or various CNC lathes operated by robots; vertical lathes with a motorised spindle (totally flexible and adjustable to numerous geometries), and dual head auto-feed lathes.

Machining centres

- Mori Seiki 400 single-spindle machining centre

- Single-spindle machining centres (Matsuura 630): 4 axes

- Brother single-spindle machining centres: 4 axes

- Multi-spindle machining centres SW 400/4: 4 axes

- Multi-spindle machining centres SW 600/2: 4 axes (1 of 5 axes)

- Multi-spindle machining centres SW 600/4: 5 axes

- Multi-spindle machining centres SW 400/2: 4 axes

- TriFlex Transfer machining centre 5 stations, 5 axes

Lathes

- Mori Seiki horizontal lathes with power tools

- CNC horizontal lathes

- CNC vertical lathes

- CNC vertical lathes, 2 headstock

- Nakamura 2 headstock and 3 turrets

- Visual control (Vision cameras)

- Air leak detection test in different processes

- Grinding machine (1 Danobat Glider)

- Mitutoyo 3D machinery

- Profilometer

- Hexagon 3D machinery

Our precision machining process includes a number of steps to shape parts based on specific plans and manufacturing means. CNC machining means we can manufacture parts in the following:

- STEEL

- STAINLESS STEEL

- ALUMINIUM

- BRASS

Our existing partners

Our disruptive multi-technology synergies have become the solution of choice for ground-breaking companies that share our e-automotive vision.

Do you want to innovate too?

The automotive market is introducing efficient and sustainable solutions. And so are we.

At MEK we embrace your challenges. Your mission is our mission.